Our Recent Achievements

CSIR-CSMCRI has been recognized as being among the top institutions of CSIR and has a good world ranking as well. The institute fares among top innovators with a very good IPR portfolio. In 2020-21, 19 patents were granted abroad while 22 were granted in India. More than 220 peer-reviewed publications were published with an average impact factor of around 4.5. The Institute also produces around 30 Ph.D. every year under the supervision of scientists who are also the faculties under the Academy of Scientific and Innovative Research ( AcSIR;). In this context, it is noteworthy that several research scholars have received prestigious recognitions like UGC-Dr D.S. Kothari Postdoctoral Fellowship, Newton Bhabha Ph.D. placement programme, Research Explorer Ruhr Program, Water Advanced & Research Innovation Fellowship, Marie-Curie Fellowship, DST-SERB NPDF, JSPS-Post Doctoral Fellowship, MK Bhan Young Researcher Fellowship Program and RMIT (Australia)-AcSIR cotutelle Ph.D. Recently, one of our scholars has got an opportunity to join the research group of Prof. Sir Fraser Stoddart (2016 Nobel Laureate in Chemistry) at Northwestern University, USA.

It has achieved this feat through its eight scientific divisions working, many a time in collaborations, in different areas within the Institute’s mandate. They are Salt & Marine Chemicals, Inorganic Materials and Catalysis, Analytical and Environmental Science & Centralized Instrument Facility, Natural Products and Green Chemistry, Process Design and Engineering, Applied Phycology and Biotechnology and Plant Omics. The activities carried out have been of support to society, industry and forms a basis for various government policies.

Salt and Marine Chemicals domain focus improvement of quality as well as yield of solar salts from seawater brine and sub-soil brine available in different soil producing regions of the country. A dedicated group of scientists in this domain undertakes customized process optimization based on the properties of brine. The institute aids the industries by scientifically designing the layout of salt works, providing guidance for mechanizing them, advising with best chemical treatment processes, and suggesting ways to increase their efficiencies. The group also develops economically viable and environmentally clean technologies for producing other value-added products from brine as well as other waste streams of various salt-related industries, including low sodium salt, muriate of potash, sulphate of potash, high purity magnesia, green bromine, and other specialty chemicals, valuable chemicals from tannery effluents, recovery of sodium sulphate from salt refinery/salt washery wash liquor containing sodium chloride and sodium sulphate, are examples to name a few. Through their cutting-edge research, the institute has left its valuable footprint in the areas on liquid salts (ionic liquids), extraction of valuable elements such as strontium and lithium from bittern and has extended this expertise to recovery from spent lithium batteries. On the socio-economic front, this division helps in the development and demonstration of model salt works including training to small and marginal salt workers as well as to NGOs and industries. Recently, a 5TPH salt washing unit and sodium sulphate recovery plant was successfully installed in Didwana, Rajasthan at a client’s site. The work done in this domain has won several accolades in the form of awards, recognition and the institute is numero uno in the country on this domain, as evident by a large number of patents, peer-reviewed publications, and technology transfers to user industries. Recently, a video documentary "Worth their Salt” bagged the Jury Award at 6th IISF 2020, overs some of our efforts.

Integration of sodium sulfate recovery plant with salt washery

Inorganic Materials and Catalysis Division, working for the last three decades on the theme of “Fine Chemicals and Catalysis” & “Functional Inorganic Materials”, has contributed immensely uplifting the knowledge on catalytic transformation using both homogenous and heterogeneous catalytic systems, that finds applications in chemical, pharmaceutical, agrochemical, and perfumery industries. It is identified with research on zeolites, precipitated and shaped silica, calcium salts like PCC, calcium silicate, styrene oxide, 2-phenyl ethanol, camopholenic aldehyde, carveol, mefrosol, chiral epichlorohydrin, functionalized castor oil derivatives, iso-eugenol to name a few. The scientists in the division have good international exposure and are adept in reaction chemistries like hydrogenation, hydrodeoxygenation, hydroformylation, asymmetric transformation, selective oxidation, isomerization, degradation, C-H/C-O bond functionalization, and fatty acid methyl esterification (biodiesel), wherein many of them have seen successful technology licensing and commercialization. The division has expertise in the domain of biomass-derived chemicals & polymers, in particular, furan compounds like 5-hydroxymethyl furfural, furfural, furanic polymers, diols/polyols, levulnic acid derivatives like -valerolactone, arylated lactones, levulinate ethers/esters/bis-arylated esters to name a few. The division has recently engaged in adsorption of CO2 using porous MOFs and conversion of CO2 to value-added chemicals (as part of CCUS) like formic acid, methanol, organic carbonates. Synthesis of active pharmaceutical ingredients (APIs) and cost-effective synthesis of key starting materials is another important domain the division pursues, wherein a successful demonstration is the cost-effective indigenous synthesis of COVID-19 relevant camostat mesylate. Other domain expertise includes those on porous and nanomaterials, smart-gels, and lithium recovery from electronic waste. Silver nano-based aqueous hand sanitizer against pathogen is one technology that was recently developed and transferred in COVID times.

Analytical and Environmental Science Division & Centralized Instrument Facility is another prominent division that develops new functional materials, discrete organic/inorganic molecules, metal-organic frameworks, nano and composite materials, and also engages in the development of analytical methods for sensing/recognition of targeted ions/molecules including bio-molecules/metabolites. Computational studies expertise of this division allows a deep fundamental insight into the domains of crystal morphology of inorganic compounds including common salt, molecular sensors, enzyme interaction with small molecules, and inhibitors that aid in the development of materials and devices. The interest of the scientists includes the development of cost-effective electrodes for electrochemical measurements, optical level switches (), sensing equipment, and spectroscopic measurements like fluorimeter, potentiostat, kit for rapid bacterial detection, portable curd strip. Environmental impact assessment is a key area that has seen much industry interaction with this division and CSIR-CSMCRI is accredited with NABET in distilleries, port, harbour and dredging, shipbreaking yard, and common effluent treatment plants. In the environmental research domain, expertise has been built in coral bacterial interaction, bioremediation of industrial waste including that by constructed wetlands.

The Natural Products and Green Chemistry Division aims to utilize coastal resources such as seaweeds, microalgae, and halophytes for making value-added products with the lowest environmental load, cutting back on energy and water use and effluent discharge. The major scientific outcome of this division is the development of downstream processing of economically important seaweeds creating a broad portfolio of products such as biostimulants, agar, agarose, carrageenan, and alginates. The scientists associated have successfully carried out work on the dissolution and derivatization of biomacromolecules in neoteric benign solvents such as ionic liquids and deep eutectic solvents. The other research activities of the group include homogenous catalysis, organo-catalysis, metal-free catalysis for synthesis, and site-selective functionalization of various heterocyclic compounds, C-C, C-heteroatom bond formation via C-H bond activation, synthesis, and bioassay of heteroatom fused small organic molecules. Several technologies have been transferred including those for seaweed polysaccharides of food, pharma, and bacteriological grades, biostimulants, green bromine, biodegradable films and capsules, water-soluble chitin. Recently, the process for selective extraction of pure lac resin from aqueous effluent of Shellac industry has been developed and licensed. Zero liquid discharge process for alginic acid and its derivatives and liquid seaweed plant biostimulant from Sargassum are some of the other technologies that have been recently transferred to industries. Intense efforts are also being attempted for the extraction of bio-actives like melanin, lipopeptides, etc. from halophytes for pharmaceutical & cosmeceuticals applications.

Membrane Science and Separation Technology Division stand out as another important member of CSIR-CSMCRI family whose endeavors have allowed the Institute to achieve technological prominence and socio-economical relevance through its activities on water purification/desalination for providing safe drinking water. The division is actively working on eco-friendly membrane-based technologies to treat brackish, seawater, and industrial wastewater through its cutting-edge research on all types of membranes including those used in reverse osmosis, ultra-filtration, nano-filtration, hybrid, hollow fibre water purification, and ion-exchange separation. Several large-scale RO desalination potable drinking water plants based on thin-film composite (TFC) membranes have been installed in different states of India based on CSIR-CSMCRI’s expertise with capacities ranging from 500-100000 liters per hour. Technological prowess also is evident by the installation of plants abroad, for example in water parched Afghanistan. More recently, in 2020-21, successful installation of seven RO plants (six 1500 LPH and one 1000 LPH capacity) has been done in Ramanathapuram district, Tamil Nadu that would serve roughly 10000 people’s water needs. The division has expertise in membrane distillation, forward osmosis, electrodialysis, and development of ion-exchange resins & polymeric adsorbents for selective removal of arsenic and fluoride from aqueous systems. Special mention may be also made on the development work being done on indigenous polymer electrolyte membranes for energy conversion (fuel cells) and membrane separators for energy storage (redox flow batteries). Our scientific pursuits of antifouling nano/ultra-filtration membranes, hydrophobic UF membrane, single-stage desalination membranes, rejuvenation, and reuse of used/discarded membranes (know-how for rejuvenation of end-of-life fouled/discarded RO membranes has been standardized through a pilot facility set up) are on a high note and track and hopefully, we will make a dent on these pursuits in the next 1-2 years. A RO and UF technology laced mobile desalination van drawing power from its own engine has been designed and developed by CSIR-CSMCRI, which has proved to be helpful in providing safe drinking water to people in times of natural calamities like tsunami, cyclones, droughts, floods, and earthquakes and this has proved its usefulness over and over again in different states.

The Process Design and Engineering Division is another pillar of the Institute involves in process development, scale-up, engineering solutions & integration, process de-bottling, and engineering troubleshooting for several industrially important products/processes developed by the Institute. The division plays an important role during the technology demonstration process and technology transfer. The specific expertise of the division involves technologies related to waste from wealth like potash from alcohol distillery effluent (spent wash), effluent management of textile, dyes and pigment industry wastes, separation technologies for carbonates, sulphates and chlorides of ammonia, sodium and potassium using phase equilibria, iron and iodine incorporated double fortified table salt, biofuels. Recently, in 2019, a 60 KLPD commercial plant, based on a US Patent granted technology, to recover potash and other value-added by-products from spent wash generated by a distillery in Maharashtra has been successfully set up and is operational. This division also works in the area of renewable energy, solar thermal energy applications, and thermochemical conversion.

The Applied Phycology and Biotechnology Division specializes in science-based advancement of the seaweed and microalgae sector. The division has scientific expertise on both culture of seaweeds as well as its applied aspects. The mission of the division is to generate knowledge and innovations that would help to establish seaweed cultivation as a new form of agriculture that is remunerative, eco-friendly, sustainable, and expansive in scope. The division is also engaged in activities in the field of molecular biology and biotechnology of marine macro and microalgae with an aim to utilize the potential of these coastal and marine resources. The simultaneous objective is to use the seaweeds as a novel plant genetic resource, utilizing the unique genes to develop improved germplasm/cultivars of agricultural land plants. CSIR-CSMCRI, through this division, takes pride in the development of cultivation technology of several economically important seaweeds like Kappaphycus alvarezii, Gracilaria edulis, Gracilaria debilis, Gracilaria dura, Gelidiella acerosa, to name a few. It has also developed tissue culture technology and spore-based technology for the production of quality seed material of seaweeds. In January 2021, Shri. Giriraj Singh, Hon’ble Minister of Animal Husbandry, Fisheries, and Dairying, while launching a Seaweed Mission Project at our Marine Algal Research Station, Mandapam, handed over these elite seaweed materials to the women fisherfolk of Ramanathapuram. CSIR-CSMCRI has been the pioneer in ushering the first successful Kappaphycus cultivation in Indian waters, which has enabled the coastal population in Tamil Nadu to get significant additional income. Technology developed to produce sap (biostimulant) and carrageenan (phycocolloid) by processing fresh Kappaphycus heralded the era of commercially farming and valorization of seaweeds in India. The scientists of this division have contributed to popularizing the indigenous biostimulant from seaweeds across India by coordinating multi-locational multi-crop in collaboration with Agricultural Universities across 20 states in India and demonstrated 11-37% crop yield improvement by use of seaweed biostimulants. The biostimulant products developed by the division have been licensed to various entrepreneurs and are very popular among Indian farmers. One of the products is being marketed by IFFCO. The environmentally benign effect of the use of seaweed biostimuants has been also proved by the life cycle assessment approach and is important from policy point of view. The science behind the action of biostimulants on crops has been elucidated comprehensively, making CSIR-CSMCRI technology and knowledge hub in the field of seaweed biostimulants. Besides, the division has initiated intense efforts in the development of food algae like Ulva, Monostroma, Porphyra, and Entromorpha and efforts are on to develop their culture including land-based cultivation strategy. Very recently, the division has developed seaweed-based animal feed formulation additive for enhancing the productivity and health of animals, which has now been licensed to an industry. Nanofertilizers, biofertilizers, and microalgal research are other areas the division is actively pursuing research. Due to the gained expertise on both upstream and downstream aspects of seaweeds, the Institute has been regularly consulted by several ministries of the Government of India for the national consultative action plans and policy formulation.

Plant Omics is another division actively involved in biological research in the Institute. It is actively involved in exploiting the genetic resources of halophytes and xerophytes for the genetic engineering of crop plants to develop transgenic abiotic and biotic stress-tolerant crops. Transgenic tobacco, sesame, and tomato have been developed by overexpressing stress-responsive genes and transcription factors like AIHKT2, NAC, DREB, AlRab7, etc isolated from halophytes. The research of this division is also focused on understanding the mechanism of abiotic stress tolerance of halophytes using a biochemical, physiological, metabolomics approach. Salicornia brachiata, Salvadora persica, Haloxylon salicornicum, Sueda maritime are the plants on which extensive understanding has been generated concerning abiotic stress tolerance brought about by modulations in metabolic pathways, photosynthesis, ionic and homeostasis, and anti-oxidative defense system. The division has standardized cultivation practice of the halophyte called Salicornia brachiata that can be used to produce herbal salt—another technology developed by the Institute. In a first kind of its own, genome sequencing of Salicornia brachiata is in the advanced stage of being accomplished and it currently engages in genome sequencing of Recretohalophyte Aeluropus lagopoides (L.). In addition to these, studies on population dynamics, phenology, nutrient cycling, microbial community dynamics study, and isolation of salt-tolerant plant growth promoting rhizobacteria (PGPRs) are under the active purview of the divisional research.

Several projects both from CSIR and from industry/other government agencies are undertaken on all these above domains with an endeavor to deliver translatable outcomes.

COVID Efforts: The entire S&T community, across the globe, has been cohesively fighting to meet the COVID-19 challenges and CSIR is no exception. This difficult period has raised the expectations of the public at large from our scientists. CSIR-CSMCRI has been active in contributing in various verticals – right from the preparation of reusable 5-layered membrane-based masks to aqueous hand sanitizer and disinfection chambers. More than 35000 masks have been distributed to doctors, nurses, front-line workers, government functionaries, etc. in Gujarat and beyond. Scientists of CSIR-CSMCRI have been involved in developing a method for the complete synthesis of Camostat Mesylate (which is a targeted repurposed API for the treatment of COVID19) and its intermediates in a cost-competitive manner, by majorly utilizing indigenous raw materials. It is expected that with this intervention from CSIR-CSMCRI, the cost of the targeted API will be significantly lowered (reduction by ca. 20-30%). Currently, the process is being up-scaled to 25 g. Researchers at the Institute have designed an effective face shield that complies to test qualification as per ANSI/ISEA Z87.1-2015. This lightweight face shield has a frame that is made of LDPE and a visor made of polycarbonate. An interesting study was undertaken (recently published) where environmental impact at Alang Ship-breaking yard, was assessed – in view of COVID-19 lockdown- with an endeavor to generate a kind of baseline data, that revealed a drastic reduction in air-quality parameters signifies the relationship between anthropogenic activity and its influence in the environment. Research is ongoing for the development of a process for zeolite-X, an adsorbent used in oxygen concentrators, with an endeavor for Atma-Nirbharta. During the last 18 months, CSIR-CSMCRI’s work towards creating COVID-related social awareness amongst the local population has also been a key driver. It is pertinent to mention some of these efforts are made possible but for the collaboration with institutes like NIOH, Ahmedabad, and THSTI, Faridabad.

COVID-19 efforts @ CSIR-CSMCRI

In its endeavor to quench the thirst of our society, the Institute installed a 1200 LPH brackish water RO plant at Shree Somnath Sanskrit University in Gir Somnath district of Gujarat and a 0.1 MLD brackish water desalination plant for our Nation’s defense forces in a forward post of Bhuj region in Kutch through GWSSB (more than 1000 defense and allied personnel would be benefitted through this plant). CSIR-CSMCRI has joined hands with a Vadodara-based industry that specializes in membranes to fine-tune the methods for the production of hexane resistant polymeric membrane modules, intended for its deployment in the vegetable oil refining industry for energy efficiency. Furthering its mark in the area of membrane sciences, CSIR-CSMCRI has recently transferred the process for the preparation of inter-polymer cation and anion exchange membranes to a public limited company in Ahmedabad. As a scientific social responsibility, the institute has deployed its newly made mobile desalination plants (thanks to a Fast Track Translation project funded by CSIR) in the aftermath of the Tauktae cyclone that devastated Rajula and Jafrabad, Amreli, Gujarat, and floods in the Konkan region (Mahad, Raigad) of Maharashtra by providing clean drinking water from diverse contaminated waters sources to several tens of thousands of people, who otherwise faced acute shortage of drinking water.

Mobile desalination plant serving water to the people of Gujarat (after Tauktae cyclone in May 2021) and Maharashtra (after heavy floods in Konkan region in July 2021)

In addition, our team at MARS, Mandapam has distributed elite tissue cultured plantlets to 50 commercial seaweed growers of Ramanathapuram District. CSIR-CSMCRI has also successfully completed the APSSDC funded feasibility study on farming of seaweeds in coastal regions of Andhra Pradesh and hands-on training on seaweed cultivation for the coastal community. Team CSIR-CSMCRI’s study at Ramanathapuram, Pudukottai, and Tuticorin districts for expanding the seaweed cultivation through seed production is ongoing under Pradhan Mantri Matsya Sampada Yojana (PMMSY). Likewise, another team is spearheading the activities of assessing commercial cultivation in the Andaman & Nicobar Islands, by identifying sites and exploring pre-feasibility studies under PMMSY. These projects are some of the enablers in realizing the country’s dream of augmenting seaweed production capacity to over 1 million tons in the next five years.

This year too, the Institute has given a non-exclusive licence for the process for the preparation of Liquid Seaweed Plant Bio-stimulant (LSPB) from Sargassum to an Ahmedabad-based company and integrated process for seaweed sap and carrageenan to a MSME in Tamil Nadu. Our institute has transferred know-how related to “Kappaphycus alvarezii and red seaweed-based formulations for improving productivity and health of dairy and poultry animals”. This work is also unique in the sense that the know-how is an outcome of a NMITLI project and had an R&D partnership with IVRI, NDRI, AVRI, and CSIR-IITR. CSIR-CSMCRI has also been able to identify an industrial partner to upscale and validate its process for the synthesis of pinene oxide and alpha-campholenic aldehyde. Recently, the Institute has transferred its know-how on the extraction of pure lac resin from the aqueous effluent to a West Bengal-based MSME. The institute boasts of an impressive technology transfer with stakeholders through technologies developed.

The institute has also carved a vibrant technological partnership with NIOT, Chennai for promotion and implementation of seaweed, microalgae, and desalination research in the country and IIT, Gandhinagar for promotion of collaborative research in the area of chemistry, chemical processes engineering, membranes, materials to name a few. We have also signed MoU with Crescent Innovation Incubation Council & Thassim Bheevi Abdul Khadhir College for Women, Tamil Nadu for women empowerment, and Venture Centre, Pune for improving the technology transfer avenues.

On the infrastructure front CSIR-CSMCRI’s capability, Central Instrumentation Facility at this institute brings around 40 state-of-art instruments housed under one umbrella to give access of their use to all scientists of the institute. Besides, this is also accessible to industries, universities, and other Institutes of India. To augment further in the area of surface science research, it has included recently X-ray Photoelectron Spectrometer (XPS), a facility unique of its capability in Gujarat, India. It was a moment of elation for Team CSIR-CSMCRI to witness the new tissue culture laboratory at MARS, Mandapam being inaugurated by Dr. (Smt.) Suverna Chandrappagari, IFS, NFDB. In addition, in February 2021, CSIR-CSMCRI’s de-centralized multistage constructed wetland for sewage treatment having 2000 LPD capacity was inaugurated by Shri Varun Kumar Baranwal, DDO, Bhavnagar.

Seaweed Tissue Culture Laboratory @ CSIR-CSMCRI Marine Algal Research Station, Mandapam, Tamil Nadu

The Government’s clarion call for attracting CSR funding has been answered by the institute. CSIR-CSMCRI has collaborated with Pidilite Industries Limited for enablement and capacity building of local farmers and fisherfolk community towards seaweed farming. Similar discussions are underway with prominent clients for the deployment of desalination plants for providing drinking water, solar dryers for food drying, solar stills for drinking water for remote coastal habitats, spectrochemical/electrochemical devices for schools/colleges etc.

CSIR-CSMCRI’s skill development training courses, a program orchestrated under CSIR Integrated Skill Initiative, in the areas of solar thermal gadgets, soil & water testing, chemical process plants, fermentation technology, and seaweed cultivation & processing have been greatly admired by the community at large. In the year 2020-21 over 250 people have been skilled on these programs, while in the current year, a target of roughly 400 people to be skilled is set wherein roughly half is achieved at the end of September 2021. As part of the “CSIR’s 80 years 80 Success Stories” CSIR-CSMCRI’s work on Spent Wash Management Technology was covered by the USD, CSIR HQ and relayed through diverse social media platforms. To moot the scientific spirit among school children, under an interesting program Jigyasa, over 1600 students and 140 teachers were sensitized through 14 different programs before COVID in FY 2019-20. In this FY, as on September 2021, 500 students and 40 teachers are sensitized where several of our scientists talked about recent S&T topics.

Skill Development Programs @ CSIR-CSMCRI - CSIR Integrated Skill Imitative

CSIR-CSMCRI’s research work is being routinely published in some of the most reputed and high impact factor journals like ACS Applied Materials & Interfaces, ACS Applied Polymer Materials, ACS Catalysis, Advanced Functional Materials, Applied Catalysis B-Environmental, Chemical Communications, Chemical Science, Carbohydrate Polymers, Desalination, Green Chemistry, Journal of Hazardous Materials, Journal of Materials Chemistry, Progress in Polymer Science, etc. The work of CSIR-CSMCRI has been acknowledged by way of several prestigious awards and recognitions. The Institute’s agarose technology was conferred with the prestigious “DBT-Biotech Product, Process Development and Commercialisation Award 2020”. CSIR-CSMCRI’s young scientist Dr. Ketan Patel was one amongst the team that received the 10th National Award for Technology Innovation in the category of “Innovations in Polymeric Materials”. Very recently, Dr. Shilpi Kushwaha has been awarded the prestigious CSIR Young Scientist Award for 2021 under “Earth, Atmospheric, Ocean and Planetary Sciences” for her research contributions on the extraction of uranium from secondary sources like seawater and acidic effluents.

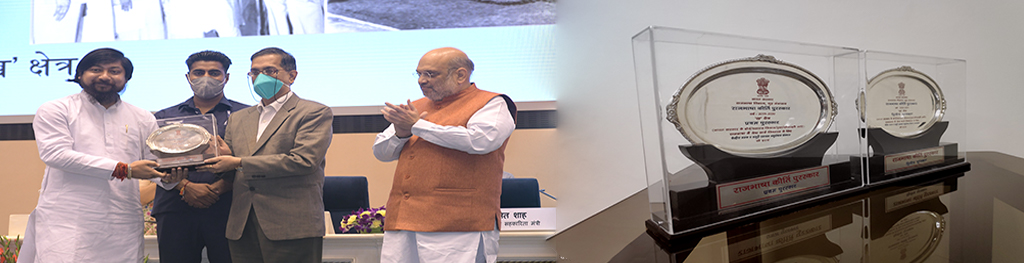

Department of Official Language, Ministry of Home Affairs, Government of India has selected CSIR-CSMCRI for the best implementation of the Official Language Policy in the 'B' region of the country for the National 'Kirti Puraskar' for the year 2019-20 with First prize and 2020-2021 with Second prize (back to back). Awards for both the years 2019-2020 and 2020-21 were given on the occasion of Hindi Diwas on 14th September 2021 at Plenary Hall, Vigyan Bhawan, New Delhi by Hon'ble Home and Cooperation Minister Shri Amit Shah and Hon’ble Ministers of State Shri Nityanand Rai, Shri Ajay Kumar Mishra, and Shri Nishith Pramanik.

National 'Kirti Puraskar’ – First Prize for 2019-20 and Second prize for 2020-21

YSA-2021 Award to CSMCRI Scientist Shilpi Kushwaha "Method to extract Uranium From Secondary sources"

The above-mentioned activities and achievements provide a spectrum of the major activities of the Institute. We cordially welcome visionary stakeholders, sponsors, and end-users to browse through our site to get a better in-depth feel of the work being done by our S&T staff and visit us if you find something exciting to take forward. The Institute is committed to engaging in cutting-edge scientific research that supports industry and society.