Title of Process/ Know-how/ Product/Design/Equipment

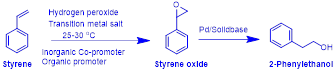

Technology for the production of 2-phenyl ethyl alcohol (2-PEA): A synthetic rose aroma by hydrogenation of styrene oxide obtained via non-chlorine route from styrene

Application/Uses/Problem being addressed

2-PEA is directly used as a rose fragrance in soap industry and in syrup formulations in pharmaceutical industries. 2-PEA is also a starting material for many industrially important aroma chemicals (e.g., synthetic Kevra) and bio-active compounds.

Salient Technical Features including Competing Features/ Impact

TRL Level & Scale of Development:

Pilot scale (1 Kg)

Business scope & opportunity (in terms of scale, cost, market etc.):

2-phenylethanol (2-PEA) is a naturally occurring rose fragrant chemical currently used as aroma chemical in perfumery, cosmetic industries and in pharmaceutical formulations. The industry uses Pd/C as hydrogenation catalyst for the production of 2-PEA from styrene oxide which is pyrophoric besides producing several by-products, and due to its low physical strength, there is physical loss of the catalyst during recovery operations. Perfumery industry is expanding and 2-PEA would find improving indigenous market opportunity.

Environmental Considerations:

Benign process with low effluent load owing to use of reusable urea-like organic promoter for epoxidation

Status of Licensing:

Licensed technologyTechnology licensed to-

Status of Commercialization:

CommercializedSome of the licensee have started putting up a plant for commercial scale manufacture of SO/2-PEA though details of their scale of manufacturing is not known

Major Raw Materials Needed

Styrene, Solid urea, manganese sulphate, water, hydrogen peroxide, toluene, ethyl acetate and dichloromethane, Pd/solid base, hydrogen

Major Plant Equipment and Machinery Required

Reactor, high pressure reactor, distillation unit, centrifugal/filtration unit

Techno-Economics

Attractive and tentatively the product cost would be ~2-2.5 times that of styrene; Available on request;

Technology Package

Know-how for 2-PEA and SO; Demonstration of the process; License fee, royalty and other financial details are available on request.