Title of Process/ Know-how/ Product/Design/Equipment

Technology for development of sustainable concrete saltpan bed to reduce the brine percolation using industrial waste materials for solar salt works

Application/Uses/Problem being addressed

The traditionally compacted salt bed has nearly 15-20 % brine losses through percolation/seepage. The proposed technology of sustainable concrete bed will provide a fascinating alternative to prevent brine losses through percolation from bed of crystallizer, pre-crystallizer and bittern ponds.

Salient Technical Features including Competing Features/ Impact

Problem to be addressed:

TRL Level & Scale of Development:

Business scope & opportunity (in terms of scale, cost, market etc.):

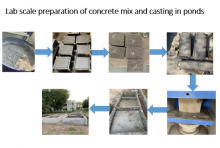

The salt demand is increasing and feasible coastal land is limited for salt production, which leads to a consistent increase in demand of salt and rise the salt price. The present system is to increase the salt yield by reducing the losses of brine due to percolation in existing salt pond area. The salt production can be increased by reducing the percolation losses by providing concrete beds replacing the natural salt beds. For the development of the concrete beds numerous trials have been done with different waste materials. From the trials done, optimum percentage is obtained for each of the waste materials, which is suitable for creating the concrete beds.

Environmental Considerations:

This is an eco-friendly process and sustainable and green solution using sustainable concrete. It is produced without cement with the combination of other industrial waste materials.

Status of Licensing:

Ready for transferStatus of Commercialization:

Not applicableMajor Raw Materials Needed

Industrial waste such as fly ash, Bottom ash, replacement of aggregates with construction waste etc.

Major Plant Equipment and Machinery Required

Concrete mixer, Weighing balance, compressive strength testing machine, flexural strength testing machine.

Techno-Economics

The losses of brine through percolation from bed as per type of soil, and loading conditions during mechanized operations. Present practices of reducing brine percolation is not economical and the economical methods are not providing long-term solution and cannot prevent significant losses of brine in all conditions.

Use of HDPE liner is costly i.e. per ace cost is approx. Rs.10 lakhs and there is a risk of breakages while mechanized harvesting. The life of HDPE liner is limited. The proposed technology of sustainable concrete is cost-effective.

Prevents percolation in saltpans, life of Sustainable Bed is around 15 to 20 years, No need to leave salt bed of 6 inches. It will provide good compressive strength to withstand mechanized salt extracting and harvesting operations using heavy machines.

Technology Package